Description

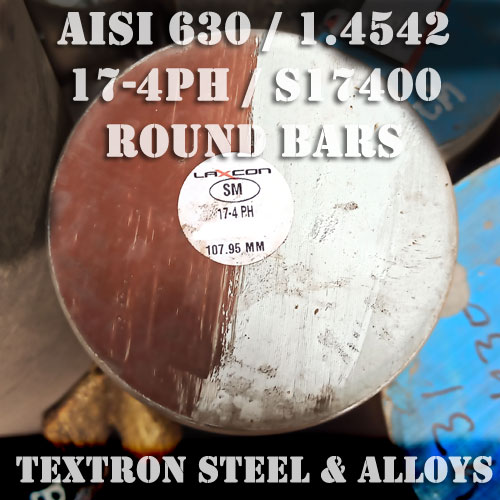

AISI 630 Round Bars

AISI 630 Round Bars is a hardenable, martensitic stainless steel with high wear resistance, good corrosion resistance and high yield strength. By combining excellent mechanical properties and high corrosion resistance, AISI 630 can be used in a marine environment, but in standing seawater it is susceptible to crevice corrosion.

17-4 PH is manufactured in several strength levels, for example: in solution annealed (AT) and hardened versions (H900, H925, H1025, H1075, H1100, H1150, H1150M).

The AISI 630 material can be use in temperatures up to 450°C, but also suitable in the low temperature range. At minus temperatures an excellent impact strength is given. Steel 1.4542 can be machined in solution-annealed and hardened condition, but the machinability depends on the hardness. AISI 630 is used in the aerospace, chemical, petrochemical and petroleum industries, in medical and dental technology, in plant construction and in shipbuilding.

Grade AISI630 Round Bars stainless steels are martensitic stainless steels that are precipitation hardened to achieve excellent mechanical properties. These steel achieve high strength and hardness following heat treatment. The heat and corrosion resistance of grade 630 are similar to that of grade 304 steels. This grades is also commonly referred to as grade 17-4PH.

One of the key benefits of this grade is that it is available in solution treated conditions, at which they can be easily machined and age-hardened to attain high strength. The age treatment of grade 630 is carried out at low temperatures, to avoid significant distortion. Therefore, this grade is used for applications such as the manufacture of long shafts that do not require re-straightening after heat treatment.

AISI 630 Chemical Composition :

| Grade | AISI 630 | |

| min. | max | |

| C | – | 0.07 |

| Mn | – | 1.00 |

| Si | – | 1.00 |

| P | – | 0.040 |

| S | – | 0.030 |

| Cr | 15.00 | 17.50 |

| Ni | 3.00 | 5.00 |

| Cu | 3.00 | 5.00 |

| Nb+Ta | 0.15 | 0.45 |

Equivalent of AISI 630 :

- • Grade – AISI 630

- • EN X5CrNiCuNb16-4

- • Material No. 1.4542

- • AFNOR Z7CNU17-04

- • BS X5CrNiCuNb16-4

- • UNS S17400

- • JIS SUS630

Applications of AISI 630 Grade :

SAE 630, 17-4PH and X5CrNiCuNb16-4 / 1.4542 is provided in the form of round bars, sheets, flat bars and cold-rolled strip. The material is widely used in the aerospace, marine, paper, energy, offshore and food industries for heavy-duty machine components, bushings, turbine blades, couplings, screws, drive shafts, nuts, measuring devices.

- • Engine components

- • High strength and boat propeller shafts

- • Plastic moulding dies

- • Valves and gears

Cities We can Supply our AISI 630 / 17-4PH / 1.4542 Round Bars to :

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal, Hyderabad, Itanagar, Dispur, Patna, Raipur, Panaji, Gandhinagar, Chandigarh, Shimla, Srinagar, Jammu , Ranchi, Bengaluru, Thiruvananthapuram, Bhopal, Mumbai, Imphal, Shillong, Aizawl, Kohima, Bhubaneswar, Chandigarh, Jaipur, JajPur, Gangtok, Chennai, Agartala, Lucknow, Dehradun, Kolkata, Visakhapatnam, Vijayawada, Guntur, Nellore and Tirupati, Visakhapatnam, Vijayawada, Guntur, Nellore and Tirupati, Guwahati, Tezpur, Dibrugarh, Silchar and North Lakhimpur, Gaya, Biharsharif, Darbhanga and Bhagalpur, Bilaspur, Korba, Durg-Bhilainagar, Raigarh and Rajnandgaon, Vasco-da-Gama, Ponda, Margao, Mapusa and Goa Velha, Ahmedabad, Surat, Rajkot, Junagadh and Vadodara, Faridabad, Gurgaon, Sonipat, Panipat and Ambala, Dharamshala, Mandi, Solan, Bilaspur and Chamba, Anantnag, Leh, Udhampur, Ramnagar and Baramulla, Bokaro Steel City, Jamshedpur, Deoghar, Hazaribagh and Dhanbad, Mysore, Davangere, Mangalore, Hubli-Dharwad and Belgaum, Kochi, Kozhikode, Thrissur and Malappuram, Indore, Gwalior, Jabalpur, Ujjain and Sagar, Pune, Nagpur, Nashik, Aurangabad and Solapur, Bishnupur, Ukhrul, Tamenglong, Chandel and Senapati, Cherrapunji, Tura, Jowai, Baghmara and Nongpoh, Lunglei, Serchhip, Champhai, Tuipang and Mamit, Tuensang, Zunheboto, Mokokchung, Kiphire Sadar and Phek, Rourkela, Cuttack, Brahmapur, Puri and Sambalpur, Amritsar, Jalandhar, Ludhiana, Patiala and Kapurthala, Bikaner, Jaisalmer, Jodhpur, Udaipur and Ajmer, Bikaner, Jaisalmer, Jodhpur, Udaipur and Ajmer, Tiruchirappalli, Madurai, Erode, Vellore and Coimbatore, Warangal, Nizamabad, Karimnagar, Adilabad and Khammam, Warangal, Nizamabad, Karimnagar, Adilabad and Khammam, Noida, Varanasi, Allahabad, Agra and Kanpur, Haridwar, Roorkee, Rishikesh, Kashipur and Haldwani, Darjeeling, Siliguri, Asansol, Howrah and Durgapur, Andaman and Nicobar Islands, Chandigarh, Dadra and Nagar Haveli, Daman and Diu, Lakshadweep, NCT of Delhi, Puducherry, Port Blair, Chandigarh, Silvassa, Daman, Kavaratti, New Delhi.